http://www.leoshoemaker.com/files/HEXBeam_by_K4KIO.pdf

HEX BEAM

Step 6: Assembly

Now that you have built the components for your hexbeam, all that remains is to assemble them into a completed beam. Just follow these steps.

1. Set the base plate on a table, a 10 gallon paint bucket filled with water or rocks to serve as an assembly foundation.

Assemble the spreaders and insert them into the baseplate using the U bolts. All the P clips on the spreaders should be on the top side of the spreaders. Make sure each spreader is in line with the opposite spreader and if not, then loosen the U bolts and readjust. Do not over tighten the U bolts as you can easily crush the spreaders. If the spreaders are starting to flatten, you have tightened them too much.

2. Install the center post into the baseplate and tighten the two set screws snugly. Do not over tighten as they will penetrate the center post.

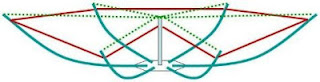

3. Install the support cords between each spreader end and the anchor eye bolt on top of the center post. The easiest way to do this is to hook one cord on the end of one spreader and another on the end of the opposite spreader. Then, standing in the middle, pull both cords up simultaneously and hook them on the center post eyehook. Repeat this process for another spreader pair and then another as shown here.

Fasten the cords to the ends of the spreaders as shown in step 5.

4. Install the wire sets starting at the highest frequency band. Attach one end to a terminal for that band and then fish the other end through each of the P clips on the spreaders. Then attach the other end to the second center post terminal. If the wire will not reach the terminal without excessive tension, then loosen the P clips for that band and let them slip inward about 1/2 inch each or until the wire reaches. Take small steps in this for better results. Do not have the wires over taut. This only distorts the shape of the beam and makes the remaining wires harder to adjust. Tautness does not improve beam performance at all. A little slack is better.

5. After installing all wire sets, make adjustments so that all wires have generally the same slack and the overall shape of the beam is balanced and symmetrical.

6. Connect the coax to the top of the center post to the 20 meter terminal. Use a small piece of coax at first in order to make SWR tests before going further. You should see an SWR dip for each band but the lowest SWR will not be achieved until the beam is raised 20-30 feet.

If you do not get a dip in SWR, make sure all connections of the wires are tight in the terminals including the coax links. When finished, be sure to seal the terminals and coax ends to keep moisture out as contaminated coax will not perform correctly on the beam.

73 and Good DX´s

FAQ’s

1. Why should I be considering a broad band beam?

Because it performs better than the classic hex beam. And on top of that it is easier to build and easier to adjust. The only drawback is that it is slightly larger in diameter by less than three feet.

2. Are the wire lengths critical?

A. Well, if you change the wire length for the reflector on 10M by one inch, it changes the design frequency by about 130 kHz. Two inches would be about 260 kHz, and so on. You can do a simple ratio of frequencies to figure the change in wire lengths.

Change in wire length (+,-) = Change in frequency (-,+) X Orig. wire length / Original frequency

(Remember, increasing frequency requires decreasing wire length and vice versa.)

If you change the reflector lengths be sure and do the same for the driver wires.

3. How important are the tip spaces?

A. They affect the front/back performance and the SWR and are designed for the optimal balance of these two performance criteria. But if you are off an inch or even two, it isn’t going to make a lot of difference.

4. What if I want to use a different gauge of wire than 16 gauges?

A. That is fine. Just use the Conversion Table on this page to scale the driver wire lengths shown here for your particular wire thickness. The reflector wire gauge is relatively immune to differences in wire thickness so just use the table amounts for 16 gauges. Also, leave the end spaces as they are shown here.

5. How high should the hex beam be?

A. Higher is better for DX generally as it reduces the takeoff angle of the main RF lobe. However, the hex beam can be quite effective even at modest heights. Some say 40 feet is optimal but really, if you can get it higher for DX, go for it. Try to get 20 feet at least.

6. What about use of steel wire or aluminum instead of copper?

A. You will need new dimensions based on conductivity of those materials. The dimensions here are strictly for copper.

7. What about stranded wire or solid wire?

A. Either is fine.

8. What about insulated wire?

A. It can be used and if it is the specific wire in the table here you already have the specs. But you can’t depend on these specifications for all other insulated wire.

9. How important is spacing on the center post?

A. Post spacing is mainly determined by the geometry of your particular hex beam. Try to get your wires generally parallel, level with the ground, symmetrical, etc. Spacing can become a problem if they are too close. In particular, it has been found by some that if the 10 meter wires are too close to the 12 meter wires, the two bands can interact with each other. If you can’t get the specified 4 inch spacing between 12 and 10 meters while keeping the 10 meter wires parallel, that’s OK; just pull the wires down the post a bit; performance will be better.

10. Should I feed the hex beam at the top or the bottom?

A. Top feeding will provide better results overall.

11. Should I connect the bands with wire or coax?

A. Coax will provide better results. Use 50 ohm coax.

12. Do I need a balun?

A. It is a good idea because it prevents surface currents flowing on the exterior of the coax and thereby distorting the radiation pattern. The best price for a ferrite bead balun I have found is at www.palomar.com.

13. Can I substitute materials if those on the parts list aren’t available?

A. Well, sure. Your substitutions might be better than mine. Just be sure you know the physical factors that are important and make judicious choices. There are only a few things truly critical about the details of a hex beam such as wire length, general

shape, etc.

14. Where can I learn more about the hex beam theory?

A. Visit the web site of Steve, G3TXQ. (http://karinya.net/g3txq/hexbeam/)

15. Can I buy a broad band hexagonal beam?

A. Thought you’d never ask. Seriously, I am selling a multi-band hexagonal beam on another web site that is already built. You just assemble five modules when you get it and it works with no tuning. DX Engineering sells a kit of parts with illustrated instructions to build a broadband hexagonal beam. Is it as good as mine? Well, I’m sure it’s a good product but be prepared to do more work than you would do with one purchased from me. You get over 200 parts and a 38 page manual.

YB Land DX Club DX-ing Is Our Life

YB Land DX Club DX-ing Is Our Life