http://www.leoshoemaker.com/files/HEXBeam_by_K4KIO.pdf

HEX BEAM

Step 4: The Wire Sets

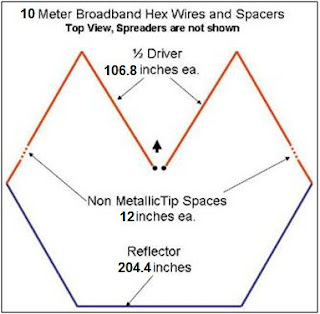

• The driven element will consist of two pieces of wire for each band. The reflector will also consist of one piece of wire for each band. Each driven element piece will be shaped by the hex beam structure into an inverted “V” and when arranged next to the other piece, will form a “M.” Each Reflector piece will be wrapped around the four spreaders and attached to the tip spacers which in turn are attached to the driver wires. Be precise with

cutting the wires as an inch can make a difference in the resonant frequency of that band.

• Each outer half of the driver wires has a non-conducting line that connects that wire to one end of the reflector wire. These non-conducting lines will be called “tip spacers.” The length of the spacers is important to proper performance of the hex beam and they are designed here so they can be adjusted precisely.

• The two ½ driver wires, the reflector wire and the two tip spacers should be measured and assembled as single end to end sets before installation on the spreaders using the approach below for each band.

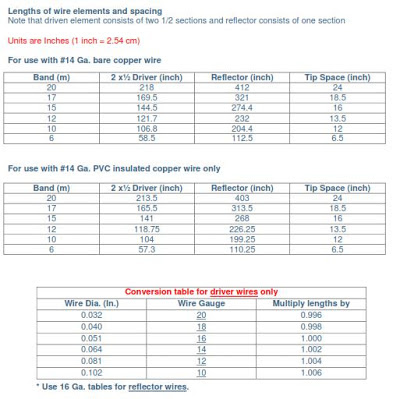

• The higher frequency bands are nested inside the lower frequency bands but only one band is shown here for the sake of simplicity. The wire lengths are for #14 or #16 gauge bare wires. Insulated wire can be used in salt water environments and the lengths will be shorter. Tables for the lengths are on the next page.

For each band, make sections as shown here and then connect the pieces altogether for a single wire assembly that will look like the photo above when strung on the beam.

Use the table on the Specifications page for the lengths to measure and cut as shown above. You will need one set of the elements above for each band on your hexbeam. The cords can be made of Kevlar which has very little stretch or Dacron. When finished, connect all the pieces together for a complete wire assembly.

Measure the half driver wire using the length found on the Specifications page. Include the ring terminal in the measurement and also add 1/2 inch for bending the other end into an “L” shape for insertion into the center post terminal. Repeat this for the other half driver wire for others meters.

Then measure out the reflector wire per the Specifications page and solder a ring terminal on each end. Include these ring terminals in the measurement. A good way to handle the measurement process is to use a nail in a board so you can anchor the wire while stretching it out on the floor or driveway.

Be very careful with the measurements. It is not fun to have to solder a piece back in that was mistakenly cut off. So remember the old carpenter’s adage.

Measure once; cut twice or measure twice and cut once.

See more details:

Here is an assembled wire set with the reflector coiled in the middle and the two half reflector wires coiled on the ends. The cord knots to the wires are covered with heat shrink but the heat shrink is not really necessary

YB Land DX Club DX-ing Is Our Life

YB Land DX Club DX-ing Is Our Life