http://www.leoshoemaker.com/files/HEXBeam_by_K4KIO.pdf

HEX BEAM

Building the G3TXQ Broad Band Hexagonal Beam Six Steps to build it:

The electrical design of this hexagonal beam is the same as the beam featured in the March 2009 QST article by the author. However, the mechanical details here differ somewhat and are an improvement, in my opinion, over the mechanical design in the QST article. The guidelines here are for a six band hexagonal beam.

However, if only three bands are desired or five bands, the same specifications apply for the bands you want to equip. The cost for materials for this beam are around $300 retail and sources for some key parts are on line while most of the small parts are obtainable from Home Depot or Lowes.

The approach in this site is to explain five steps for building the components shown below and then Step 6 outlines how they are all assembled into a hex beam.

Step 1: The Base Plate

• The baseplate is made of a 12 inch square type 6061 T6 aluminum plate that is 3/16 inch thick.

This particular type aluminum is harder than pure aluminum and less likely to bend while being resistant to weather. U-bolts attach the spreaders to the baseplate.

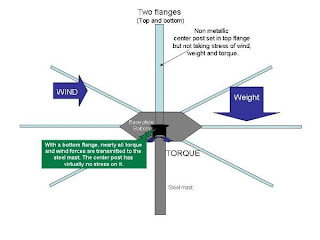

• Two square base floor flanges normally used for handrails are used to mount the center post to the base plate. One is on the top for mounting the center post and the other is on the bottom for insertion of the mast. These flanges are made of aluminum-magnesium alloy.

• Stainless steel hardware can be used to minimize corrosion especially in saltwater environments although it is more expensive. Lock washers should be used; otherwise movement of the hex beam by wind and rotation will eventually work the fixtures loose.

Don’t want to cut and drill and chase down all these parts? Get the plate already cut and drilled and all hardware tools for under $90. Your cost for parts and shipping will be close to this if you go ahead and built it yourself so why bother? See the details at www.hexkit.com

Six Steps to build it – The Base plate:

Measuring and marking the hexagon. Bellow more details on how to do this.

See more details:

The plate can be cut with a hacksaw by hand or by a reciprocating saw with a metal cutting blade. A piece of board and clamp are used to hold it all steady for cutting.

See more details:

A metal hole saw and a hand operated drill can be used to easily cut out the center hole.

There is a rule in all building and repair projects. You will have to buy at least one new tool. This metal hole saw from Lowe’s cost about 8 dollars and I’ll probably never use it again.

The holes for the U bolts are carefully cut where the lines have been measured. If you have a drill press, the holes will be more accurately cut. If you look closely you can see some of mine are a little short of perfection.

The center post will fit snugly into this floor flange. Put one on the top and bottom of the base plate for greatest strength. Bellow why is better this tip:

Why two flanges is a good idea?

YB Land DX Club DX-ing Is Our Life

YB Land DX Club DX-ing Is Our Life